PURIFIED Water System

Purified Water is tested

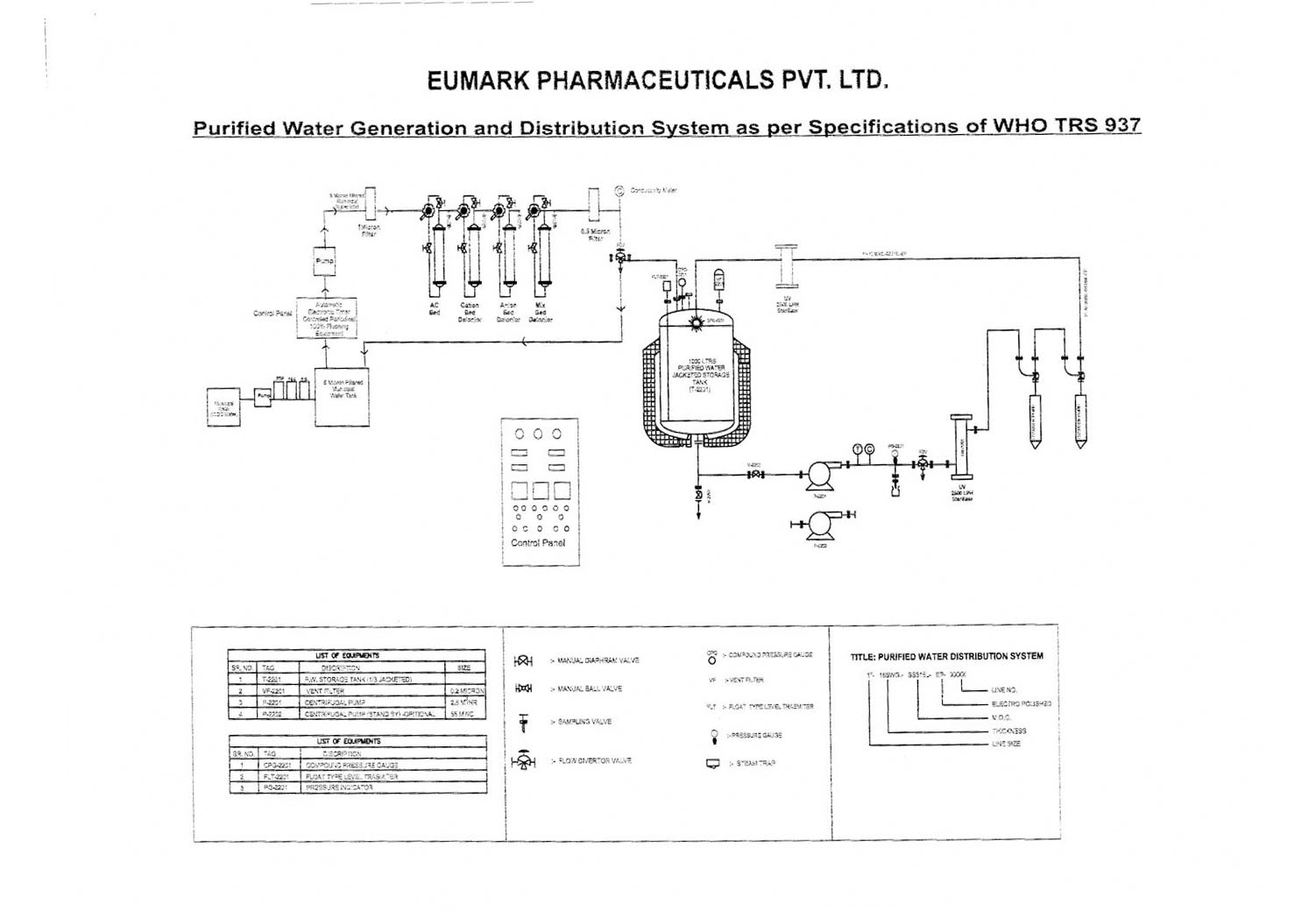

Water Purification and Distribution Systems as per WHO TRS 929 Specification

Municipal (MIDC) water is filtered through High Integrity 25 µ, 10 µ. and 5 µ. Filters. Filtered Water Collected in a clean tank. 5 µ. filtered municipal water is further filtered through 1µ . Filter and fed to Purified water plant consisting of1.Activated Carbon, 2.Double bed ( cation, Anion beds ), 3. Mix bed demineralizer. Demineralized water is further filtered through High Integrity 0.5 µ. filter. 0.5 µ. filtered Purified Water is fed to Purified Water Storage Tank of Purified Water Circulation Loop. Purified Water Circulation Loop as per specifications of WHO TRS 929 is maintained running for 24 hrs.Preventing Microbial Growth

For preventing microbial growth within the entire system, the Purified Water Plants are controlled by Electronic Timer Controlled Automatic Water Circulation from Purified Water plants back to Purified Water Plants.When there is no requirement of Purified Water in Purified Water Circulation Loop, the Plants are kept under constant Circulation for 30 min. on & 15 min. off This Auto Circulation System operates automatically every 30 MINUTES ON AND 15 MINUTES OFF, which ensures No stagnancy of water even in the Purified Water Plants. This totally ensures that No microbial growth is possible Since no stagnation of water is ensured whether Purified Water Plants are in use or not ( during closed hours ) . Pipelines of Purified Water Circulation Loop are made of SS 316L internally Electropolished to 180 – 240 Grit to ensure no Bio-film formation and no Microbial Growth. Velocity of water in return loop is maintained at 1.2 to 1.5 mt/sec. Circulation loop is equipped with Drainable Grundfos pumps. There are NO FLANGES in the water Circulation loop. Complete Pipeline of the Circulation loop is with sections joined with Orbital Argon Welding. Sanitation of the Water Circulation Loop System is done by 70-80 Degree C. Hot Water everyday before use. Pipeline of Circulation Loop is having Gradient in every horizontal section. There are TWO U.V.Colums in outlet of the Circulation Loop Tank and One U.V. Column in return. The intensity of the U.V. Sterilizer is maintained and monitored at 250 to 300 Microwatts/sq.cm.